Let’s begin our series on appreciating value with some of the various joints you might find holding furniture together as you shop around. There are quite a few common ways to join wood pieces together. Some joining methods are longer lasting than others, some can take more pressure, some resist wear and tear better. Hopefully, this discussion will help you to recognize some of them and therefore help you determine the quality and value of the furniture you’re considering.

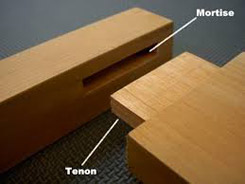

First, we’ll look at the Mortise-and-Tenon, a tried, trusted, true.

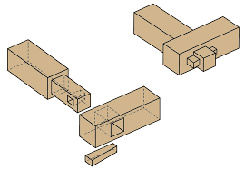

You’ve likely heard of a mortise-and-tenon joint before. These are probably the most commonly discussed wood-to-wood joints used in the furniture market. Well made mortise-and-tenon joints are very secure and require very little else to hold together. You’ll find them in everything from chairs to timberframe homes. Typically glue is used to secure the joint, and sometimes a small dowel, pin, or wedge is added for extra strength and longevity. Through tenons, where the mortise is cut all the way through a board and the tenon extends out the other side, are very common in Arts & Crafts and Mission styles of furniture. Builders can be very creative with these joints so they can have a real aesthetic function as well as practical. Look for these in chairs, tables, desks, bedframes, etc. They are used in the frames of case pieces as well. Here are a few examples of mortise-and-tenon variations.

Look for very tight connections, no wiggle, no gaps, no glue showing.

(Image: from Bob Vila’s website)

(Image: www.craftsmanspace.com)

Sometimes the pin is made in a contrasting wood, or a unique shape, or even an alternate material (metal, bone, etc) for aesthetic reasons. That doesn’t make it less functional.

(Image: www.woodworkingtalk.com)

Be sure the pin is tightly fitted, no gaps, no glue showing. Also, ask the salesperson if the pin is real. Sometimes a small piece of wood is inlaid into the piece so as to look like a pin that’s securing a tenon, when actually there is no mortise-and-tenon joint there. Sometimes the “pin” is just a plug covering a screw. Your salesperson should know the construction of the furniture they sell well enough to tell you.

(Image: www.craftsmanspace.com)

Through tenons come in many forms. In all cases, the mortise is cut clear through the board, so when inserted, the tenon comes out the other side. Sometimes the tenon is then cut flush with the mortised board, and then wedged into place. Or, a wedge can be fitted through the end of the extending tenon.

(Image: www.houzz.com)

In both cases, through tenons make for beautiful detail in furniture pieces. Builders can be so creative with the wedge shapes and materials. And, the wedges further tighten the joint making it super strong.

The wedged through tenon can be faked. Be sure they aren’t just applied to the outside of the piece for aesthetics. That would indicate that something else is holding the piece together and would require a little further investigation. Sometimes the construction is still very sound, just inquire.

(Image: FrameAndStool on Etsy.com)

You’ll often see a flush wedged tenon holding a turned chair leg to a wooden chair, stool or bench seat. Again, be sure the tenon and wedge are real, not just a pretty plug covering a screw. And again, they should be very tightly fitted with no gaps or glue showing. Also, in the case of a wedged tenon holding a chair leg to a seat, as you look down on the seat, the grain of the tenon should be perpendicular to the grain of the seat and the wedge should run in the same direction as the grain of the tenon.

So, I hope this was helpful. I’ll tackle something else to look for when shopping for furniture in the next post. If you have questions, don’t hesitate to ask us; give us a call, shoot us an email or comment here. We’re always happy to answer any questions.

Note: I will be on vacation Feb 14-22. So if you comment here, or send us an email with a question or comment, I promise to respond upon my return.